What Material Should A Water Tank Be?

In the expansive realm of industrial processes, where precision and reliability reign supreme, the role of water tanks is pivotal. These giants play a crucial role across diverse sectors, from chemical plants and manufacturing facilities to power generation and wastewater treatment plants.

Their functions range widely, from storing and supplying water to containing chemicals, effluents, and other substances. Each application requires distinct attributes, making the choice of material for these tanks a decision of paramount importance.

In this article, we will embark on a journey through the world of water tanks, dissecting the ideal materials for constructing these indispensable structures in industrial contexts.

Understanding the Landscape of Industrial Water Tanks

Industrial water tanks serve as essential storage units, ensuring a continuous supply of water for a plethora of operations. Whether as reservoirs in power plants or vessels for chemicals in processing facilities, their applications are far-reaching.

Water tanks are the backbone of water distribution systems, firefighting equipment, and wastewater treatment processes. Withstanding corrosion, chemicals, and varying temperatures are imperative, underscoring the significance of choosing the right material.

Comparing Common Water Tank Materials

When selecting materials for constructing industrial water tanks, several contenders vie for attention. Let’s delve into a detailed comparison of the most prevalent materials used in water tank construction:

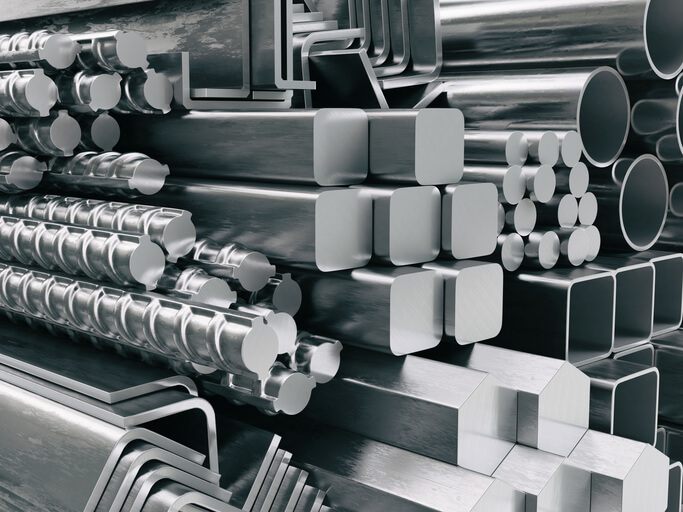

Steel

Steel, renowned for its strength and durability, has been a traditional choice for water tanks. However, its vulnerability to corrosion when exposed to moisture and chemicals necessitates the use of coatings and liners to address these concerns.

Pros of Steel:

– High structural strength.

– Widely available.

– Durable under certain conditions.

Cons of Steel:

– Susceptible to corrosion without protection.

– May require maintenance to prevent rust.

– Heavy weight that can affect transportation and installation.

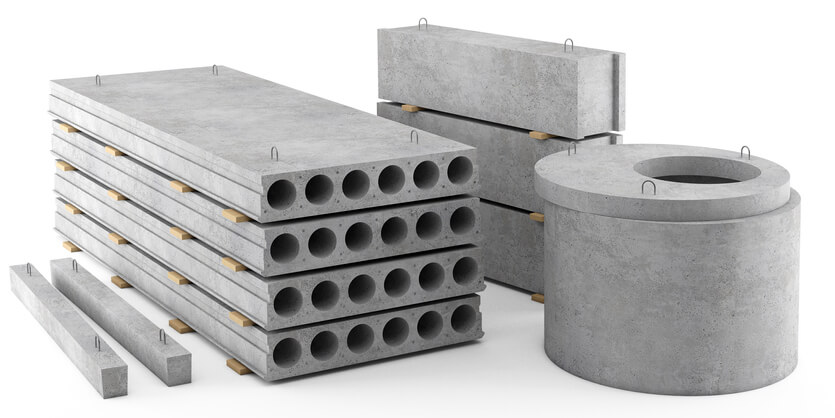

Concrete

Concrete tanks offer strength and stability, rendering them suitable for large-scale projects. While relatively resistant to corrosion, they can develop cracks and leaks over time, posing maintenance challenges.

Pros of Concrete:

– High structural integrity.

– Resistant to corrosion in certain environments.

– Suitable for large-scale applications.

Cons of Concrete:

– Vulnerable to cracks and leaks.

– Heavy and requires a strong foundation.

– Maintenance can be costly.

Stainless Steel

Stainless steel combines the robustness of steel with superior corrosion resistance, making it an appealing choice for corrosive environments. However, its initial cost and susceptibility to crevice corrosion warrant careful consideration.

Pros of Stainless Steel:

– Strong and corrosion-resistant.

– Suitable for aggressive environments.

– Minimal maintenance.

Cons of Stainless Steel:

– Higher initial cost.

– Potential for crevice corrosion.

– Limited design flexibility.

Fiberglass Reinforced Plastic (FRP)

FRP has emerged as a revolutionary material for water tanks in industrial settings. Its exceptional corrosion resistance, lightweight nature, and design flexibility make it a preferred choice.

Pros of FRP:

- Exceptional Corrosion Resistance: FRP boasts remarkable resistance to a wide range of corrosive chemicals, ensuring longevity and reliability in even the most aggressive environments.

- Lightweight Nature: Its high strength-to-weight ratio reduces transportation and installation complexities. This also leads to saving costs and time while enhancing the ease of handling.

- Design Flexibility: FRP’s innate flexibility allows for customization to suit various needs, resulting in tailored solutions that optimize industrial processes and infrastructure.

- Minimal Maintenance: Thanks to its corrosion-resistant properties, it requires significantly less maintenance compared to materials like steel. This reduces downtime and operating costs.

- Insulation Properties: FRP’s low thermal conductivity makes it ideal for applications where heat transfer is undesirable, such as insulation and heat exchangers.

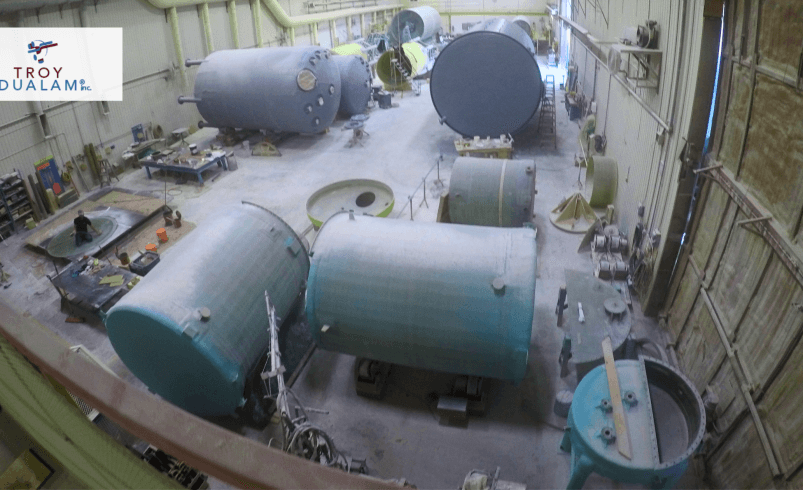

Dual Laminate

Dual Laminate tanks combine the corrosion resistance of thermoplastics with the structural strength of FRP. This innovation results in tanks that withstand aggressive chemicals while maintaining structural integrity.

Pros of Dual Laminate:

- Combined Strength and Corrosion Resistance: Dual Laminate seamlessly merges the structural strength of FRP with the corrosion resistance of thermoplastics, resulting in tanks that can endure aggressive chemicals without compromising structural integrity.

- Versatile Applications: Its unique composition allows it to excel across diverse industrial applications, offering both chemical resistance and structural reliability.

- Customized Solutions: The combination of thermoplastics and FRP in Dual Laminate provides ample opportunities for customization. Tanks can be tailored to specific requirements while maintaining exceptional performance.

- Extended Lifespan: Resistance to chemicals and corrosion ensures a prolonged lifespan, reducing the need for frequent replacements and repairs and delivering cost savings over time.

- Reduced Environmental Impact: With its durability and minimal maintenance needs, it contributes to reduced waste and environmental impact.

Ready to Elevate Your Industrial Processes?

Industrial water tanks, often unsung heroes, enable seamless operations across diverse sectors. Optimal material choice in tanks is pivotal, and among the diverse options, FRP and Dual Laminate emerge as innovative solutions. These options amalgamate durability, corrosion resistance, and design versatility. As technology advances, so does the craft of creating tanks that transcend mere storage units and become stalwarts of reliability in industrial landscapes.

In the intricate world of industrial water tanks, the choice of material reverberates across performance, longevity, and overall operational efficiency. Troy Dualam Inc. takes the lead in delivering superior solutions through FRP and Dual Laminate tanks. With unrivalled corrosion resistance, design flexibility, and innovation, our products are engineered to surpass expectations.

Let Troy Dualam Inc. be your partner in crafting tailor-made solutions that redefine the benchmarks of performance – Contact us today to get a free quote.