Unveiling Superior Dual Laminates: Myths and Facts Explored

In the realm of composite materials, the term “Dual Laminate” often sparks misconceptions. But what are superior dual laminates, and how do they stand out among traditional materials like steel? Let’s dismantle common myths and shine a light on the unmatched properties of superior dual laminates.

Myth 1: Misconception of Complexity

Dispelling the belief that working with Dual Laminate is convoluted – modern manufacturing techniques have streamlined the process. This composite material, formed by combining thermoplastics and reinforced fiberglass, offers strength and pliability.

Contrary to the myth, it’s no more intricate than working with conventional materials.

Myth 2: Underestimating Corrosion Resistance

Superior dual laminates exhibit exceptional resistance to corrosion, a misconception often overlooked. Its thermoplastic layers, reinforced by fiberglass, enable it to withstand harsh chemical and environmental conditions.

Consequently, it has become indispensable in industries plagued by corrosion concerns.

Myth 3: Vulnerability to Leaks

Addressing concerns about potential leaks, meticulous manufacturing practices ensure a seamless bond between the layers of Dual Laminate.

This attention to detail guarantees material integrity and resistance to leakage, debunking the misconception of vulnerability.

Myth 4: Susceptibility to High Temperatures

Despite assumptions, superior dual laminates can withstand elevated temperatures. While the thermoplastic layer may have temperature limitations, fiberglass reinforcement provides strength and stability under thermal stress.

Engineered to cater to specific temperature ranges, it’s suitable for diverse applications.

Myth 5: Complexity of Maintenance

Contrary to misconceptions, maintaining Dual Laminate is straightforward. Its corrosion resistance minimizes the need for constant inspections and repairs, translating to easy maintenance.

Cleaning typically involves mild detergents or solvents, highlighting its reliability and cost-effectiveness.

Myth 6: Limited Industrial Applications

The versatility of superior dual laminates transcends specific industries. While prevalent in chemical processing and water treatment sectors, its use extends to pharmaceuticals, food processing, mining, and power generation.

Its adaptability makes it invaluable across diverse sectors.

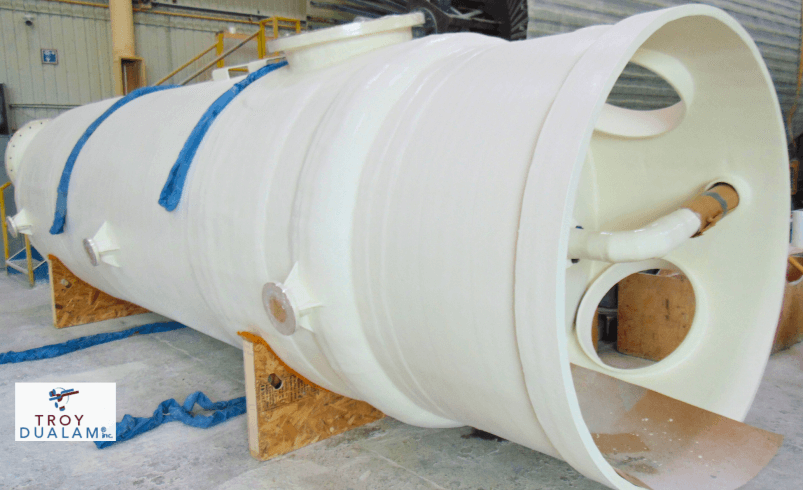

Fact: Unparalleled Customization

A distinguishing feature of superior dual laminates is their exceptional customization. Design flexibility allows manufacturers to craft tailored solutions that meet precise project requirements.

From intricate designs to unique shapes, it offers superior performance and versatility.

As myths surrounding this material choice are dispelled, the undeniable advantages come to light. Its corrosion resistance, durability, customization potential, and ease of maintenance underscore its suitability across diverse applications. At Troy Dualam Inc., we specialize in engineering and manufacturing high-quality products that epitomize the unmatched properties of superior dual laminates. Contact us today to explore how Dual Laminate can elevate your corrosion-resistant needs.