Optimizing Semiconductor Manufacturing: The Benefits of Dual Laminate Solutions

In the fast-paced and intricately precise world of semiconductor manufacturing, the choice of materials for equipment is crucial. As industries push for higher efficiency and longer-lasting solutions, Dual Laminate emerges as a superior choice – particularly tailored to meet the demands of semiconductor processes.

Here’s why semiconductor industries are turning to Dual Laminate solutions for their equipment needs, and how Troy Dualam Inc. stands ready to elevate these manufacturing capabilities.

Unparalleled Chemical Resistance

Semiconductor manufacturing involves a range of chemicals, many of which are corrosive and demand robust handling solutions.

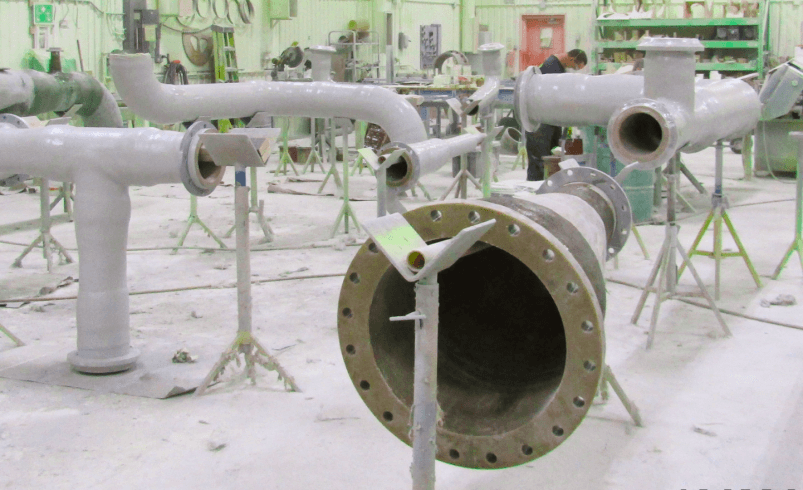

Dual Laminate combines the chemical resistance of thermoplastics with the structural strength of fibreglass – making it an ideal choice for processing harsh chemicals without degradation. This capability ensures that components like tanks, valves, and ducting maintain integrity over time, reducing the risk of leaks and contamination – critical factors in semiconductor production.

Tailored for Precision

We know that in semiconductor manufacturing, precision is non-negotiable.

The customizable nature of Dual Laminate allows for equipment to be tailored to exact specifications. Whether it’s etching tanks, wafer cleaning stations, or exhaust scrubbers, Dual Laminate can be molded and engineered to fit precise operational requirements. This both allows and ensures optimal performance and integration into cleanroom environments.

Thermal Stability

Temperature control is vital in semiconductor fabrication.

Dual Laminate materials are engineered to withstand varied temperature ranges, which is essential for processes requiring thermal consistency. Its stability aids in maintaining the critical environmental conditions necessary for high-quality semiconductor production.

Longevity and Cost-Effectiveness

The durability of Dual Laminate translates directly into cost savings.

With a longer lifespan than many traditional materials used in semiconductor manufacturing, Dual Laminate reduces the need for frequent replacements and maintenance. This longevity also means less downtime for repairs, enabling a smoother, more continuous operation – a key advantage in an industry where time is money.

Sustainable Manufacturing

As the semiconductor industry moves towards greener manufacturing practices, Dual Laminate aligns with these goals by offering an environmentally friendly alternative.

It’s durable, reducing waste and the need for frequent replacements. And its production involves less energy compared to metals, contributing to lower carbon footprints.

Troy Dualam Inc.: Your Partner in Innovation

At Troy Dualam Inc., we understand the critical needs of the semiconductor industry. Our expertise in Dual Laminate fabrication allows us to provide custom, high-quality solutions that integrate seamlessly into your manufacturing processes. With our in-house engineering team, we take your project from concept to completion without the need for preliminary drawings.

Ready to enhance your semiconductor manufacturing with Dual Laminate solutions? Contact Troy Dualam Inc. today and see how we can help transform your production landscape.