What is Fiberglass Reinforced Plastic? A Short Guide to FRP

Fiberglass Reinforced Plastic (FRP) is a game-changer across multiple industries. Whether in construction, manufacturing, or chemical processing, FRP has reshaped how we think about durability, strength, and weight savings. But what is fiberglass reinforced plastic, exactly? FRPs are composite materials, combining a polymer matrix with reinforcing fibers—usually glass fibers. This fusion creates a material that stands up to heavy loads, resists corrosion, and offers excellent mechanical properties—all while remaining lightweight compared to traditional materials like steel or aluminum.

FRP Composition: The Perfect Fusion of Materials

At the heart of fibre reinforced plastics is the polymer matrix. This plastic matrix binds the reinforcement material, which are usually glass fibres, but sometimes more specialized fibers like carbon or aromatic polyamide (commonly known as aramid) are used for high-performance needs. The resin matrix can vary—epoxy resin provides high chemical resistance, while polyester and vinyl ester are more cost-effective.

The beauty of FRP lies in its ability to be customized. Need better corrosion resistance for use in chemical plants? Building lightweight but strong walkways in marine environments? FRP composites can be engineered for specific demands, making them more than just a replacement for steel—they are a tailored solution to real-world problems.

FRP Advantages: More than Meets the Eye

One of the standout benefits of fiberglass reinforced plastic is its versatility. FRP offers substantial weight savings without sacrificing strength. Traditional materials like steel are strong, but they’re also heavy. In industries where weight reduction is critical—think aerospace, marine, and automotive—fiber reinforced plastic delivers on both fronts. Reduced weight means lower transport costs and easier installation, all of which lead to savings on both labor and maintenance.

Beyond weight, FRP shines in environments that would rapidly corrode metals. Water treatment facilities, offshore drilling platforms, and chemical plants often rely on FRP composite material for their exceptional resistance to harsh chemicals and moisture. Unlike steel, which rusts over time, glass fibre reinforced plastic stands strong in conditions that would degrade lesser materials.

Environmental Impact and Long-Term Value

While FRP is synthetic, its long lifespan and low maintenance requirements offer significant environmental benefits. The reduced need for repairs or replacements not only cuts costs but also minimizes material consumption over time. This longevity, combined with the relatively low weight and ease of transport, makes FRP a more sustainable choice in applications where traditional materials would need frequent replacement or maintenance.

The Future is Light and Strong

Whether it’s offering superior strength in corrosive environments or reducing installation times through its low weight, FRP’s advantages over traditional materials are clear. And with ongoing advancements in production processes and customization, FRP will only grow more integral in shaping tomorrow’s infrastructure.

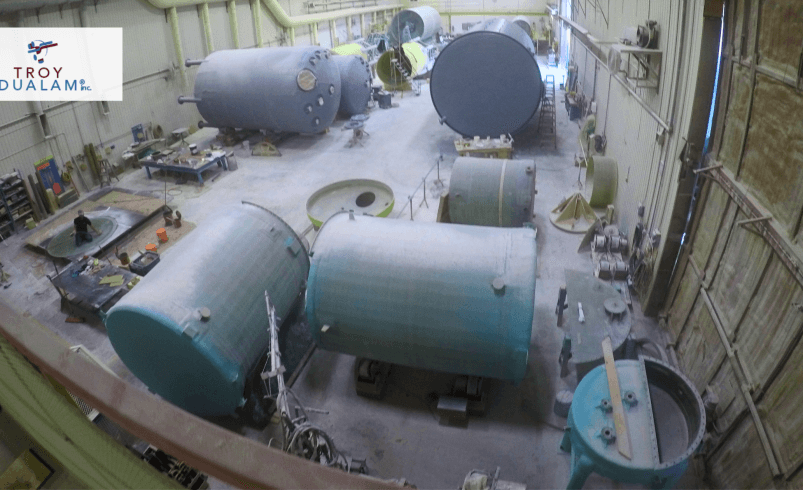

At Troy Dualam, we specialize in creating FRP solutions that meet the toughest demands, including FRP storage tanks, towers, scrubbers, hoods, piping, ducts and custom equipment. Contact us today to explore how we can customize FRP to fit your project’s needs.