Selecting the Right Material for Industrial Pipes

In the realm of industrial systems and infrastructures, pipes play a pivotal role. They’re relied on to be efficient in the transportation of fluids and gases needed for processes.

Whether it’s water distribution, chemical processing, or managing corrosive substances, choosing the most suitable material for pipes is a decision that carries implications.

Here we’ll delve into the application considerations for industrial pipes. Namely, the critical significance of material selection in ensuring performance, durability, and safety.

Understanding the Role of Industrial Pipes

Industrial pipes are the unsung heroes that enable the smooth movement of substances across intricate networks.

These pipes are integral components of various sectors including chemical processing plants, water treatment facilities, power generation plants, and more.

So the choice of material for these pipes holds tremendous consequences.

It directly influences the efficiency, integrity, and safety of the entire operation.

Industrial Pipe Material Selection Considerations

1) Corrosion Resistance:

One of the primary considerations when selecting pipe materials is their ability to resist corrosion.

Depending on the nature of the substances being transported, pipes must be able to withstand corrosive effects.

Corrosion not only compromises the structural integrity of pipes but also poses significant risks to the environment and human safety.

2) Temperature and Pressure:

The operational conditions of an industrial facility determine the temperature and pressure pipes will encounter.

Choosing a material that can handle these conditions without weakening, deforming, or failing is essential.

Careful consideration must to given to prevent accidents and ensure uninterrupted operations.

3) Fluid Compatibility:

Different materials can react with fluids in unique ways, affecting the purity and properties of the transported substances.

Compatibility is crucial to prevent contamination, reactions, or changes in fluid composition.

The right material choice can help with this.

4) Abrasion Resistance:

In situations involving abrasive materials or high-velocity flows, selecting a material with robust abrasion resistance is essential.

Failure to do so could lead to frequent maintenance, reduced efficiency, and increased costs.

5) Environmental Factors:

External elements such as weather conditions, exposure to UV rays, and potential interactions with soil should also be factored in when choosing pipe materials.

Why Material Choice Matters

Selecting the right material for industrial pipes isn’t solely about functionality; it’s about safety, cost-effectiveness, and long-term sustainability.

Inadequate material choices can result in pipe leaks, bursts, or chemical reactions with potentially catastrophic consequences.

Ongoing maintenance, repairs, and replacements due to material inadequacies can significantly inflate operational costs.

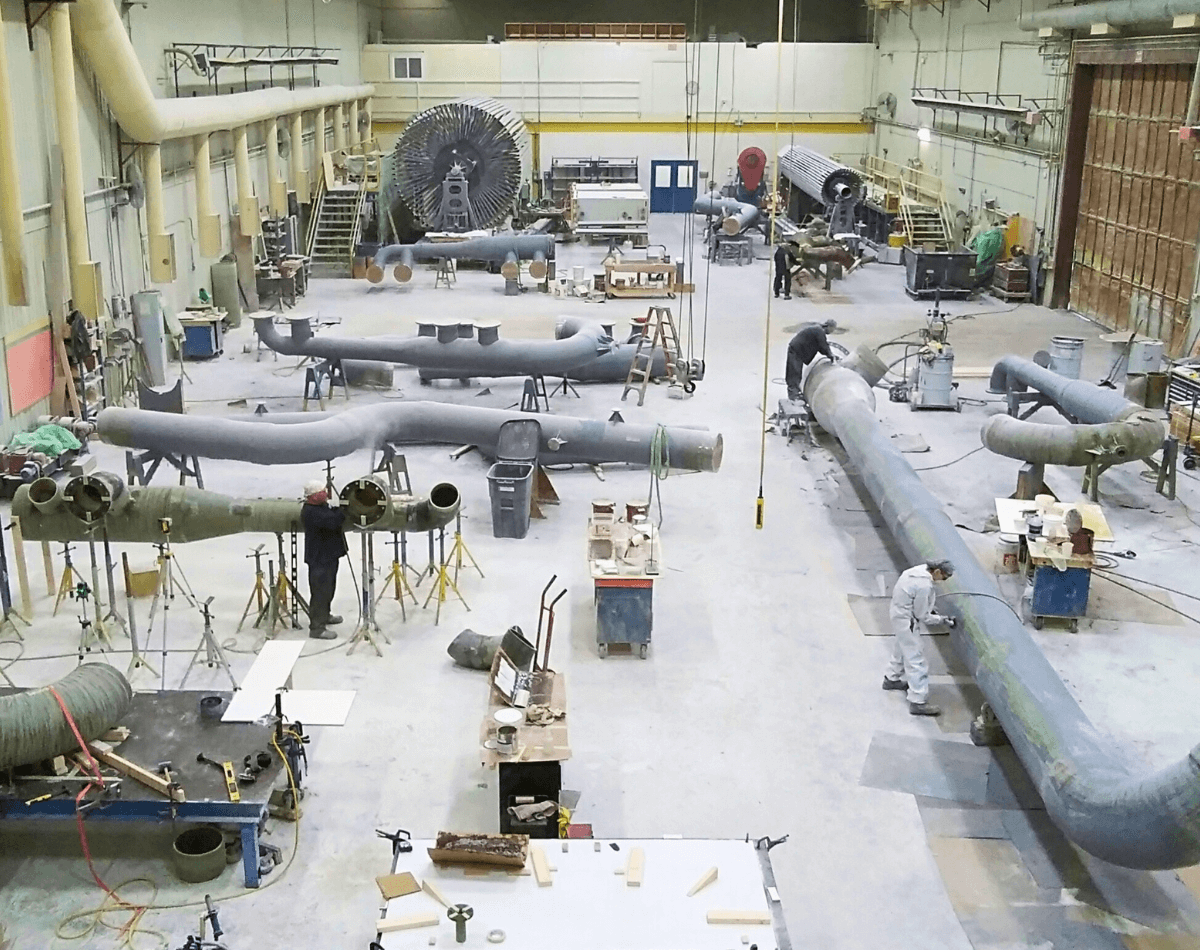

Why You Should Choose FRP and Dual Laminate

For industries seeking a reliable, versatile, and cost-effective solution, Fiber-Reinforced Plastic (FRP) and Dual Laminate pipes shine. Their corrosion resistance, lightweight characteristics, and customizable properties make them prime candidates for a wide array of industrial applications. FRP pipes offer impressive strength-to-weight ratios and exceptional corrosion resistance, while Dual Laminate pipes combine FRP’s structural strength with the chemical resistance of thermoplastics.

Both FRP and Dual Laminate pipes provide exceptional longevity, reduced maintenance requirements, and enhanced safety for various industrial operations. Their capacity to withstand corrosive substances, extreme temperatures, and high pressures ensures dependable performance and long-term cost savings.

In the intricate landscape of industrial pipes, making the right material choice is a decision that reverberates throughout the entire operation. By considering factors such as corrosion resistance, fluid compatibility, and environmental conditions, industries can ensure efficient, safe, and sustainable processes. With their exceptional attributes, FRP and Dual Laminate pipes present a compelling solution for those seeking durability, performance, and peace of mind. Connect with us at Troy Dualam Inc. to explore how FRP and Dual Laminate pipes can elevate your industrial infrastructure.